Protection Caps / Vinyl caps

You are here: Home / Products / Vinyl Caps or Protection Casps

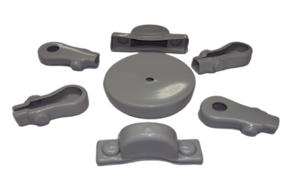

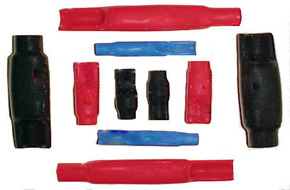

Vinyl Caps

Vindip offers vinyl caps in countless shapes & sizes by using cutting edge dip molding technology with high end infrastructure for design, development and mass production. These caps are made in plastisol and are Glossy, attractive, flexible and unbreakable in nature. Standard sizes are readily available and also can be custom made as per the customer requirement. Vindip offers numerous plastisol formulations to suit wide range of custom options like color, texture, thermal, chemical and electrical properties…

Application of vinyl caps

-

* Masking agents during painting, plating and surface finishing.

-

* To cover sharp edges of surgical and stationary articles.

-

* To shield expensive tool tips from damage.

-

* Bed frames and exercise equipment.

-

* Rods, pipe’s and bolt end caps.

-

* Dust and moisture barriers.

-

* Spark plug tip protectors.

-

* Can act as Tool grips.

-

* Electronic gadgets.

-

* Cable accessories.

-

* Thread protectors.

-

* Tube ends caps.

-

* Flange covers.

Product Showcase

-

Technical Specifications

Properties Category

Test Property

Standard Test MethodStandard Grades of Plastisol

EGR,GPR,GPBL,VDSB, HGBL,HGR,GPRB,GPYL, GPOR,GPWG,HGRY,S.GRAY,SPRFM

Specified Values*Note : All the above tests are conducted as per testing plans - ref docs QA/QIP 02/8.2 REV NO 1 and QA/QIP 03/7.2 Rev No.00 at an accredited laboratory/ inhouse lab facility Electrical Properties Dielectric Strength ASTM D149/IEC 60243 4~10kV/mm Volume Resistivity ASTM D257 1X109~1X1011Ohm Mechanical Properties Tensile Strength ASTM D638/JIS K6723 6.3~9.32MPa Elongation ASTM D638/JIS K6723 300-520% Hardness ASTM D2240 50-80 Shore A Flammability UL-94 v-0 Self Extinguishes With in 15 Seconds Tear Strength ASTM D 624 >20N/mm Thermal Properties Thermal Stability at 900C/2 hours VD001 No Cracks/blisters/ bubbles on surface Freezing (-)400C/30 min No Cracks/blisters/ bubbles on surface Retention of Tensile Strength after thermal ageing at 1200C/120 hours ASTM D638/JIS K6723 >90% Retention of Elongation after thermal ageing at 1200C/120 hours ASTM D638/JIS K6723 >40% Chemical Properties Retention of Tensile Strength After Oil ageing at 700C/4 hours ASTM D638/JIS K6723 >80% Retention of Elongation After Oil ageing at 700C/4 hours ASTM D638/JIS K6723 >50% RoHS Cd,Pb,Hg,Cr6+,PBBs,PBDEs IEC 62321:2008 Not Detected Colour -- -- -- -- Black, Gray, Orange, Red, Green, Reynold Blue, Yellow